The Different Types of CMM Machines

Manufacturing has always been a business of margins — overhead is high, the upfront costs are significant, and the success of a business often depends on finding efficiencies throughout the production line. While manufacturing had declined in North America for decades following globalization, one tool that has played an important role in its twenty-first century resurgence is the coordinate measuring machine, or CMMs.

CMM machines are perfect tools for helping to automate aspects of quality control along the production line, because they can measure the physical geometrical characteristics of an object, either with or without a human operator. Computer software makes it possible for these machines to know whether there are any defects in the parts being created on the production line, with a speed and efficiency humans cannot achieve on their own.

There are different CMM machines designed to scan parts ranging in size from metres to micrometres. Read here to get a primer in CMM machinery and learn what type of CMM equipment is best suited for your business.

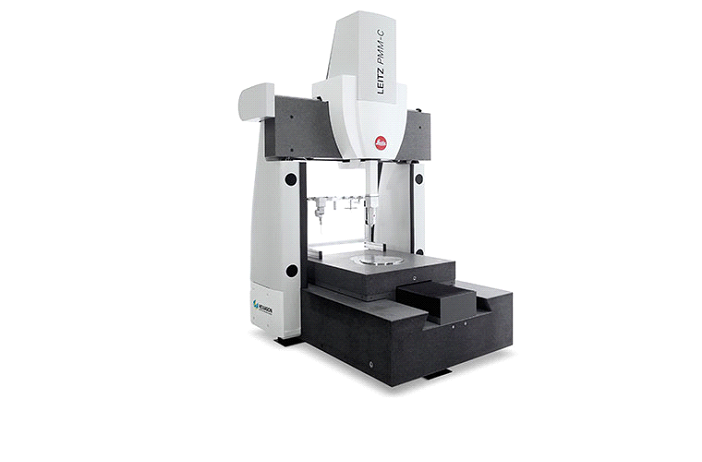

Bridge CMM

Since the 1970s, Bridge CMMs have been the mainstay of coordinate metrology. These machines are found across many industries because of their ability to handle most small- to medium-sized parts. Bridge CMMs are valued for delivering high precision and reliability at a compelling price point.

Gantry CMM

Gantry CMM machines work largely the same way as Bridge CMMs, except they are able to scan much larger parts. This makes them common in the automotive and aerospace industries, where the production line produces parts that are significantly bigger, and must be measured with extreme accuracy. For reasons that are easy to understand, accuracy in these industries is particularly important: cars and technology that is sent up to space cannot be made of any flawed parts, which is why these CMMs are designed to provide fine-grained part reports accurate to within the micrometre.

Vision and Multisensor Systems

Most CMMs measure parts and products with a tactile probe, but this is not an effective way to measure parts that are extremely small or delicate. In these cases, the parts must be measured without any physical contact being made. Video scanners and white light scanners are fast and delicate, ideal for measuring components smaller than 600 millimetres squared in area, and less than 200 millimetres tall.

Portable CMMs

The ROMER Arm is probably the most well known portable CMM machine. It is accurate and rugged, and the arm is able to move around the part or product so it can measure the dimensions of all sides.

The portable arm has an integrated scanning system which allows inspection right on the shop floor. Using a laser system or white light, it collects thousands of data points per second. It can also reverse engineer blueprints from already existing parts.

Each of these CMMs meets specific needs, and which one is best suited to you depends on the nature of your business. But competitiveness in the manufacturing industry shows no signs of slowing down, and as this industry continues to evolve, CMM machines offer a great way to use automation to improve quality control while at the same time increasing efficiency.